Without the right measures, soil erosion can cause significant damage, leading to regulatory non-compliance, structural instability, and environmental harm. Professional contractors need solutions that are not only effective but also environmentally friendly, versatile, and easy to deploy. Gravel bags are a proven, natural solution for erosion control, helping contractors meet project demands with minimal impact on the surrounding environment.

This blog will explore the advantages of gravel bags as essential contractor supplies Sonoma County, their application in professional projects, and why they should be a staple in every contractor’s kit.

Gravel bags are durable, permeable bags filled with gravel or other aggregate material. They are used to manage and control water flow, prevent soil erosion, and capture sediment on construction sites. Typically made from UV-resistant geotextile fabric, among erosion control supply products, these bags are designed to withstand prolonged exposure to the elements while allowing water to pass through.

Gravel bags come with some distinct advantages, including:

Gravel bags are relatively inexpensive to produce and maintain, making them a cost-effective option for contractors managing large-scale erosion control needs. The durable construction ensures that these bags hold up over time, even under harsh conditions.

For projects that prioritize sustainability, gravel bags provide a natural solution for choosing the right erosion control solution. Unlike synthetic barriers, gravel bags use natural aggregate materials that integrate seamlessly with the environment.

Gravel bags can be used in a wide variety of applications, including:

Diverting and slowing runoff during heavy rains.

Capturing sediment on construction sites to maintain compliance with local regulations.

Preventing erosion on hillsides or embankments.

Reinforcing drainage ditches and stream banks.

For contractors juggling tight schedules and complex logistics, the simplicity of gravel bags is a major advantage. These bags are lightweight and easy to transport when empty, and they require minimal training to deploy.

Gravel bags can be a versatile tool on any job site.

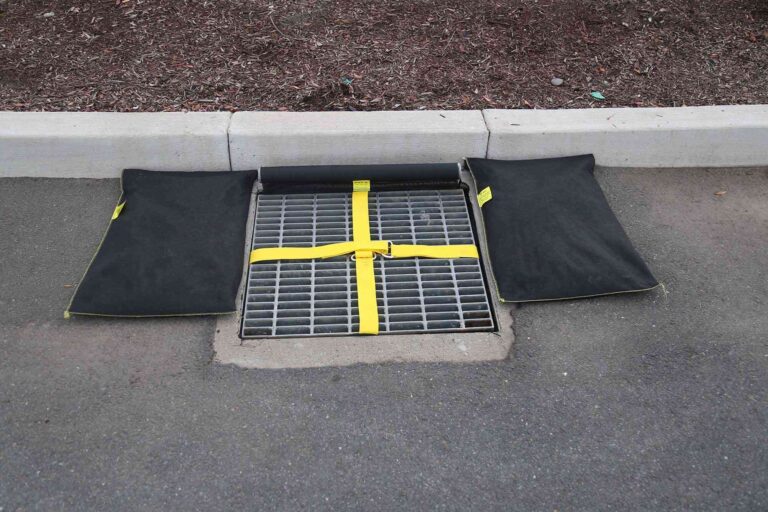

Gravel bags are often placed around the perimeter of a construction site to prevent sediment from leaving the area. This is particularly useful near storm drains, waterways, or sensitive ecological zones.

For projects involving steep slopes or embankments, erosion control is a top priority. Gravel bags can be strategically placed to slow water flow and stabilize soil, reducing the risk of landslides or washouts.

Contractors working in areas with heavy rainfall or inadequate drainage can use gravel bags to direct water flow away from vulnerable areas. Also helpful during the chilly months to protect your site from winter rain. This prevents pooling, erosion, and damage to nearby structures.

Gravel bags are an effective solution for creating temporary check dams in drainage channels. By reducing water velocity, these dams minimize erosion and help trap sediment.

Regulatory agencies often require contractors to implement sediment control measures. Gravel bags can be used to build barriers that capture sediment before it enters waterways, ensuring compliance with environmental standards.

Consider some of these tips for using gravel bags on your site:

Gravel bags are available in different fabrics and designs. For long-term projects, opt for UV-resistant bags that can withstand prolonged sun exposure.

The type of aggregate used in gravel bags can impact their performance. Angular gravel is often preferred for its ability to lock together and prevent water from washing it away.

For maximum effectiveness, gravel bags must be placed correctly. Ensure the bags form a continuous barrier without gaps and overlap them slightly for added stability.

Gravel bags should be inspected regularly to ensure they remain intact and functional. Replace any damaged or degraded bags promptly to maintain erosion control effectiveness.

Contractors have various options for effective erosion and sediment control products, including silt fences, wattles, and riprap. While each method has its strengths, gravel bags stand out for their unique combination of simplicity, versatility, and environmental benefits.

Gravel bags are a low-cost solution compared to other methods. Silt fences typically fall into the medium price range, while riprap can be quite expensive due to material and labor costs.

Gravel bags are among the easiest erosion control solutions to install. Silt fences require more preparation and anchoring, while riprap demands heavy equipment and significant effort to place properly.

Gravel bags offer high durability, performing well over time with proper maintenance. Silt fences tend to degrade faster, while riprap provides the most durability of all, though at a much higher cost.

Gravel bags are an environmentally friendly choice, as they use natural aggregate and integrate well into the landscape. Silt fences have a moderate impact, and riprap, though effective, can significantly alter the natural environment.

At Stevenson Supply & Tractor Co., we understand the unique challenges contractors face in managing erosion control. That’s why we offer high-quality gravel bags designed to meet the demands of professional projects. Our gravel bags are made from durable, UV-resistant materials, ensuring they perform reliably in even the toughest conditions.

When you partner with Stevenson Supply & Tractor Co., you gain access to:

Ready to elevate your erosion control strategy with reliable contractor supplies in Sonoma County? Visit Stevenson Supply & Tractor Co. to explore our premium gravel bags and other erosion control solutions. With our expertise and commitment to quality, we’re here to help you get the job done right.

Contact Stevenson Supply & Tractor Co. today or give us a call at (707) 575-3335 to speak with our team about your project’s unique needs. Let Stevenson Supply & Tractor Co. be your trusted partner in erosion control!